The grain of the wood always runs parallel with the lathe bed, which means that the turning tools will always be cutting across the grain of the wood. It is from this technique that long slender items and cylindrical work with shaped profiles can be produced.

The gap between the wood stock and the T-rest is 3mm. Placing a 25mm roughing gouge on the T-rest and move the bevel lightly against the stock. Gradually move the gouge along to the other end of the stock before bringing it back. Continually stop the lathe to raise the T-rest 3mm in above centre and smooth off the stock with a skew chisel. Start the cut a little way in from the tailstock and work towards the headstock. Then reverse the chisel and work towards the tailstock.

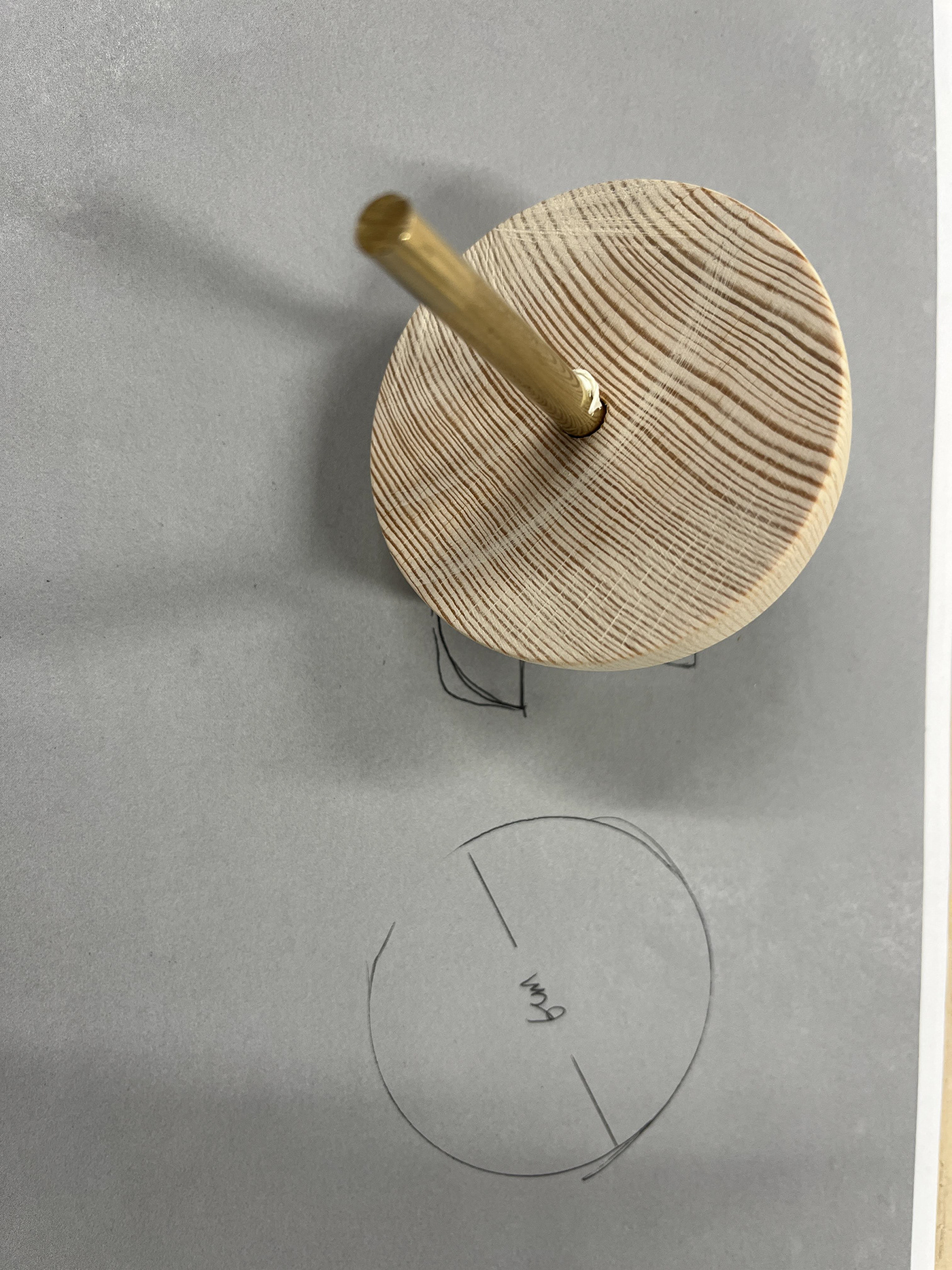

Adjust the T-rest and stock to the required angle for a curved shape, and use a skew or round-nose scraper for cutting or scraping a bead or a cove. Both are effective methods for creating a curved shape.

Glass paper to finish.